View larger

View larger

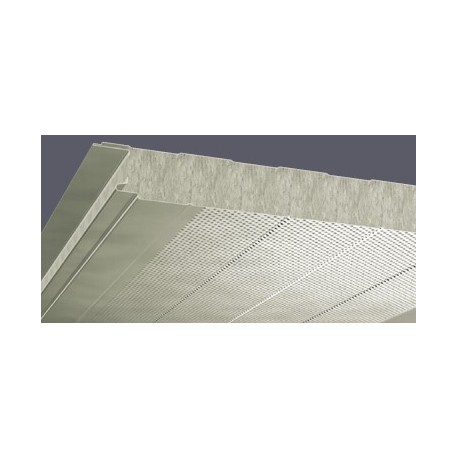

Roof ACH panel

ACH panel for facades with hidden fixings with rock wool core

The ACH panels are formed by two steel sheets adhered by organic adhesive to the rock wool core. The inner face has micro-perforations of 3 mm diameter. A fiberglass veil is placed between the perforated face and the core.

To obtain more acoustic absorption, it is possible to manufacture, with prior consultation, a panel with 5 mm diameter perforations.

The steel sheets (EN 10346) can range between 0.5 and 1.0 mm, with the standard thickness ACH being 0.5 mm. The coatings are applied depending on the use of the panel: SP25, PVDF25, PVDF35, HDS35, HDX55, PRISMA55, HPS200, etc., according to EN 10169 standard.

The standard ACH coating is 25mm polyester, SP25. It is possible to manufacture with other materials on request: aluminum, stainless steel, etc. The rock wool core complies with the EN 13162 standard.

APLICATIONS

The ACH Panels are designed for the construction of enclosures in large industrial areas or civil construction.

It can be used interchangeably for the construction of facades and interior partitions of the following types of buildings: Heated premises. Interior acoustic screening in industrial installations.

Manufacturing premises.

Locals where fire behavior is an important requirement.

Non-combustible enclosures: CPD's, garages, dangerous substances stores, etc. Buildings where the activity is changing or intended for rent.

ADVANTAGES

The advantages, being a prefabricated panel are the ease and speed in the assembly, homogeneity and quality of finishes, and their certifications.

CERTIFICATION

Classified A2-s1, d0 according to standard EN-13501-1.

FIRE RESISTANCE

Unreported property (PND).

TEMPERATURE LIMIT OF EMPLOYMENT AND WATER BEHAVIOR

- Applications from -5 ° C to + 180 ° C.

- Not hydrophilic

PRODUCT CERTIFICATION

Compliance certificate 2.1 according to EN 10204 standard

Categories

- Shop

-

Catalog

- Air conditioner

- LED lighting

- Building insulation

- Acoustic isolation

- Fire doors

- Passive fire protection

- Industrial hardware

- Work clothes

Follow us